Getting that suspension notice for a high Late Shipment Rate is a punch to the gut. It's Amazon's way of saying your fulfillment process is broken, and it’s putting the customer trust their entire brand is built on at risk. A winning Plan of Action isn't just an apology—it's a rock-solid business case that proves you've fixed the problem for good.

Why Amazon Suspends Sellers for Late Shipments

Amazon's customer obsession is the engine driving its entire marketplace. When you ship products late, you're not just missing a deadline; you're directly damaging that customer experience.

A suspension isn't meant to be just punitive. It’s a protective measure for their brand and their buyers. Before Amazon lets you back on the platform, they need absolute confidence that you can keep your fulfillment promises.

Your account health is measured by cold, hard metrics, and the Late Shipment Rate (LSR) is one of the big ones. This isn't a friendly suggestion—it’s a non-negotiable rule.

The Unforgiving 4% Threshold

Amazon’s policy here is ironclad: sellers must maintain an LSR below 4% over both a 10-day and a 30-day period. Go over that number, even for a short time, and you can trigger an immediate account review or suspension.

To Amazon, a high LSR isn't just a number. It’s a sign of deeper operational problems, like:

- Poor inventory management causing you to run out of stock.

- Inefficient packing and shipping workflows.

- Relying on a single shipping carrier who can't keep up.

- An inability to handle sudden sales spikes.

These weak spots get exposed during peak seasons. For instance, Prime Day often sees shipping delays jump by 25-35%, while the Black Friday/Cyber Monday rush can cause spikes of 40-60%. These carrier-level issues can easily double your customer service headaches, which is why Amazon polices the LSR metric so strictly. You can get the full details on their performance metrics on Amazon's official help pages.

Finding the Problem Orders in Seller Central

Before you write a single word of your POA, you need to put on your detective hat. The performance team at Amazon is looking at specific order IDs, not just your overall percentage. You have to know exactly which orders shipped late.

To find this data, head to your Account Health dashboard in Seller Central. Under "Shipping Performance," click on "Late Shipment Rate."

From there, you can download a report that lists every single order ID confirmed as shipped after its expected date. This report is your evidence. It's the data you’ll use to pinpoint the root cause and prove to Amazon that you understand the full scope of the problem. A vague apology will get you nowhere; a data-backed Plan of Action is your only path forward.

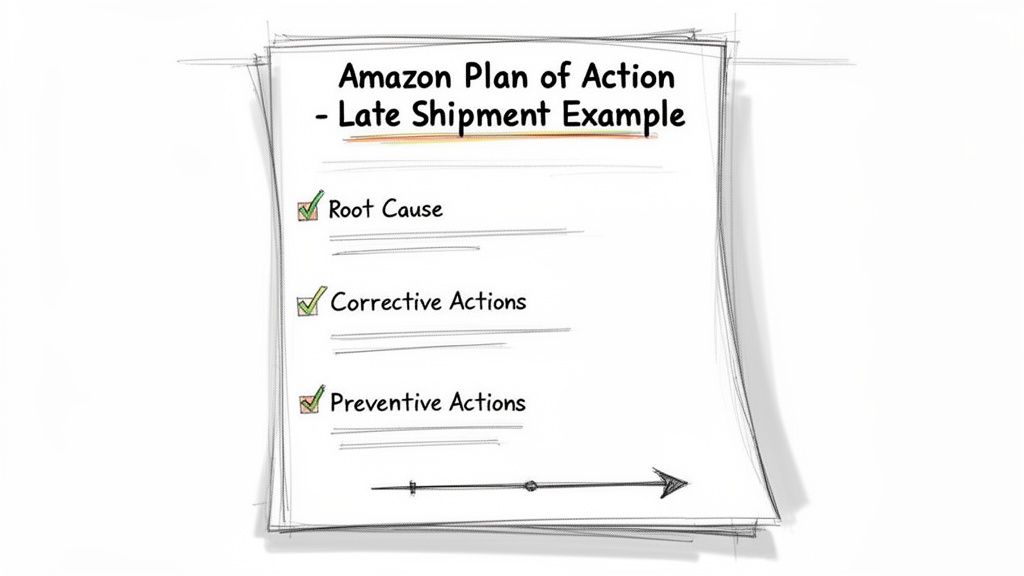

The Three Core Components of a Winning POA

Before you write a single word, you need to understand how Amazon's performance team thinks. They're not looking for an emotional appeal; they're looking for a business plan. Every successful Plan of Action is built on three specific parts. Get these right, and you're showing Amazon that you not only get what went wrong but have also built a rock-solid system to make sure it never happens again.

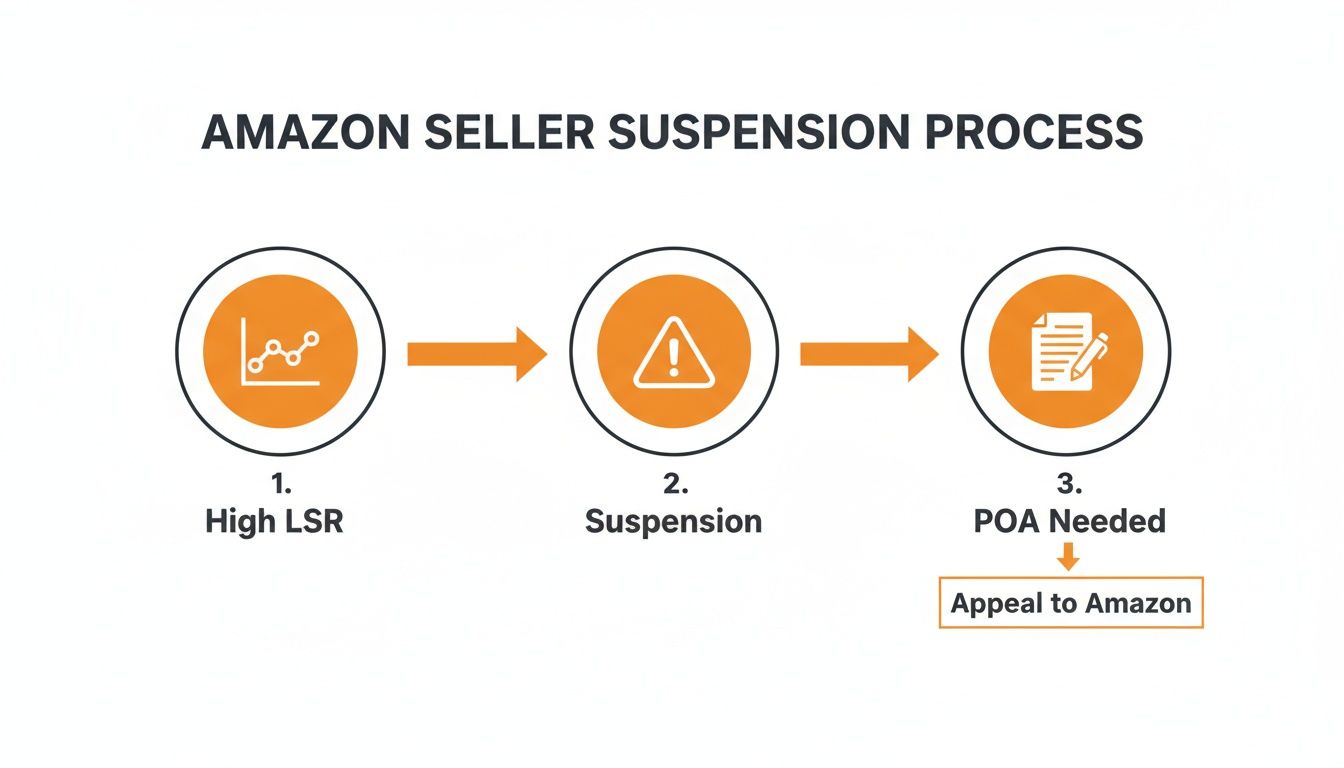

This flowchart maps out exactly how sellers land in this position. A suspension isn’t a surprise—it’s the final step after a key metric like your Late Shipment Rate goes off the rails. Your POA is the only way back.

Think of your POA as a three-act story: what went wrong, what you did to fix it immediately, and how you’ll prevent it from ever repeating.

I've seen hundreds of POAs over the years, and the ones that get approved always follow this structure. It's not a secret formula, but it is a requirement. Each section has a distinct job to do, and skipping or merging them is a common mistake that leads to rejection.

Here's a simple breakdown of what Amazon expects in each part of your appeal.

The Three Essential Components of an Amazon POA

| POA Component | Objective | Key Information To Include |

|---|---|---|

| Root Cause Analysis | To demonstrate you understand the real operational failure, not just the symptom. | Specific process breakdowns, internal system failures, and quantifiable data (e.g., "lack of a staffing protocol for sales spikes"). |

| Corrective Actions | To prove you've already fixed the immediate damage caused by the issue. | A list of actions already completed, such as contacting affected customers, auditing inventory, or updating pending orders. |

| Preventive Actions | To convince Amazon that the problem is permanently solved and will not happen again. | Systemic changes, new software, updated SOPs, and employee training protocols. This is about future-proofing your operation. |

Getting these three components right is non-negotiable. Now, let’s dig into how to execute each one perfectly.

H3: Nailing the Root Cause Analysis

This is where most sellers get it wrong. Amazon doesn’t want excuses. "Our carrier was late" or "we got a surge in orders" are symptoms, not root causes. Those answers will get your POA rejected in a heartbeat because they shift blame instead of taking ownership.

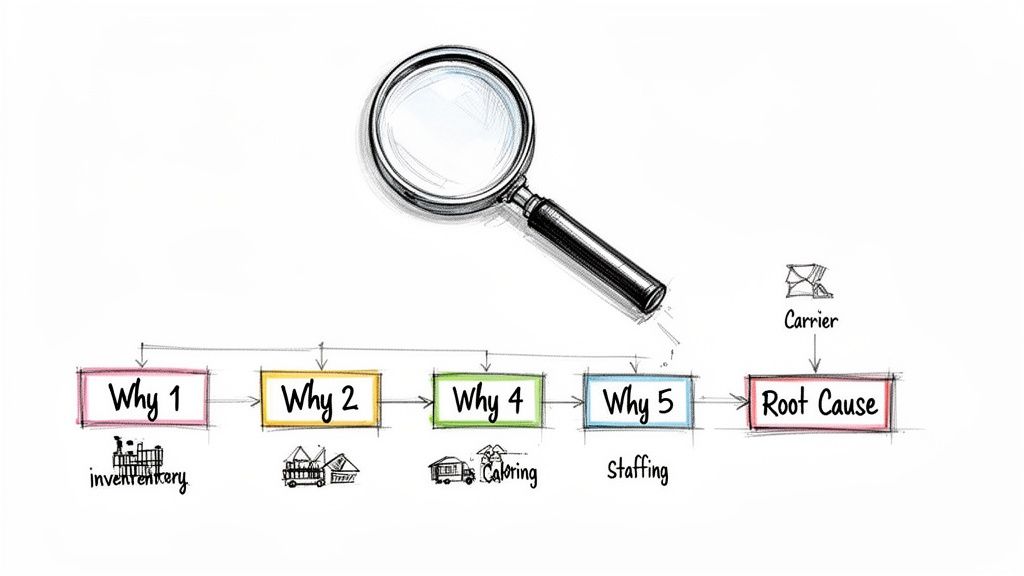

The best way to find the actual root cause is with the '5 Whys' technique. It’s simple: start with the problem and ask "why?" until you hit a core process failure.

- Problem: Our orders shipped late. (Why?)

- Why #1: The carrier didn't pick up our packages on time. (Why?)

- Why #2: We scheduled the pickup too late in the day during a busy season. (Why?)

- Why #3: Our team was buried in orders and couldn't get them packed in time. (Why?)

- Why #4: We didn't have enough people working to handle the promotional sales volume. (Why?)

- Why #5 (The Real Root Cause): Our sales forecasting isn't tied to our staffing schedule, and we have no formal process for scaling up our fulfillment team during planned sales events.

See the difference? You went from blaming the shipping company to identifying a concrete, internal business process that you control and can fix. That’s what Amazon needs to hear.

H3: Detailing Your Immediate Corrective Actions

Once you've diagnosed the problem, Amazon wants to know what you’ve already done about it. This isn't about what you plan to do; it’s about the actions you’ve already taken to clean up the mess.

This section is your chance to show you're proactive and put customers first. Get specific.

Corrective actions are all about damage control. They answer the question, "What did you do the moment you realized there was a problem?" This shows responsibility.

Your list of corrective actions should be clear, concise, and verifiable. For example:

- We have personally reviewed all 27 orders that were shipped late between [Start Date] and [End Date].

- We have messaged every affected customer through Amazon's buyer-seller messaging to apologize for the delay and provide them with updated tracking details.

- We performed a full physical audit of our inventory to ensure our stock levels in Seller Central are 100% accurate, eliminating the risk of overselling.

H3: Implementing Long-Term Preventive Actions

This is the most critical part of your entire amazon plan of action late shipment example. The first two sections dealt with the past and present. This one is all about the future. Amazon’s main goal is to be convinced that this problem is gone for good.

"We will try harder" or "we will monitor our metrics" are empty promises. You need to outline specific, permanent changes to your operations. Think systems, not intentions.

Strong preventive measures look like this:

- Systemic Change: We have implemented ShipStation to diversify our carrier options and create shipping label batches automatically, removing our reliance on a single carrier.

- Operational Update: We have permanently changed our default handling time from 1 day to 2 days in our shipping settings. This creates a necessary buffer to manage order volume fluctuations without risking late shipments.

- Process Improvement: Our warehouse manager has implemented a new daily stand-up meeting to review the previous day's order volume and confirm staffing levels for the day ahead, ensuring we are never understaffed.

These are the kinds of concrete, forward-thinking solutions that tell Amazon you’re not just sorry—you’re a more reliable and professional seller now than you were before.

How to Write a Compelling Root Cause Analysis

This part of your Plan of Action is where Amazon's performance team really separates the serious sellers from the ones just making excuses. A vague or blame-shifting root cause analysis is the fastest way to get your appeal rejected. Amazon needs to see that you've done a deep, honest, and data-driven audit of your own business.

Pointing the finger at your carrier or an unexpected sales spike is just describing a symptom, not the actual problem. The real root cause is always the internal process that failed and allowed that symptom to happen in the first place.

Go Deeper Than Surface-Level Excuses

To get to the heart of the matter, you have to dig past the obvious. Trust me, Amazon's team has heard every excuse imaginable. What they’re looking for is a seller who can prove they truly understand their own business’s breaking points.

Shipping delays are a huge challenge for everyone. In 2025, a staggering 78% of Amazon sellers reported major shipping delays that directly hammered their profits over the past year. It's turned what should be smooth operations into a logistical nightmare. Just look at container shipping times from Asia to North America—they've ballooned from a manageable 40 days to a grueling 67 days, mostly because relentless port congestion tacks on an extra 8.3 days per shipment. You can learn more about these industry-wide shipping disruptions and their impact.

But even with these macro trends, Amazon expects you to own the micro-failures happening within your four walls. Your root cause has to pinpoint a specific, internal weakness.

Common culprits I see all the time include:

- Flawed Inventory Forecasting: Your sales projections didn’t account for a promotion or seasonal spike, causing you to oversell.

- Insufficient Staffing: You had no scalable plan to bring in extra help for busy periods, and your team got overwhelmed.

- Over-Reliance on a Single Carrier: You lacked a backup shipping partner, leaving you completely exposed when your main carrier dropped the ball.

- Software Integration Failures: Your order management system (OMS) failed to sync correctly with Amazon, creating a bottleneck in processing orders.

Three Real-World Root Cause Examples

Let's make this concrete. Here are three distinct scenarios and how to frame them effectively in your POA. Notice how each example takes full ownership and uses specific, verifiable language.

Example 1: Inventory Management Failure

This example is for a seller who ran out of stock on a hot item, but their Amazon listing stayed active, leading to orders they couldn't possibly ship on time.

Weak Root Cause: "We ran out of stock on ASIN B00SAMPLE1."

Strong Root Cause: "The root cause of our high Late Shipment Rate was a failure in our inventory management process. We did not have a reliable system to sync our physical inventory with our Amazon stock levels in real-time. Specifically, a manual inventory update was missed on [Date], which allowed 35 orders for ASIN B00SAMPLE1 to be placed when we had no units on hand. This led to a significant delay as we awaited a new shipment from our supplier, directly causing our LSR to exceed the 4% threshold."

This strong example is powerful because it identifies the exact process failure (manual updates), quantifies the damage (35 orders), and names the specific ASIN. That’s what Amazon wants to see.

Example 2: Third-Party Logistics (3PL) Partner Breakdown

Here, a seller was using a 3PL for fulfillment, but the 3PL failed to meet their Service Level Agreement (SLA). The key is to take ownership of your choice of partner and your lack of oversight—not just blame the 3PL.

Weak Root Cause: "Our 3PL shipped our orders late."

Strong Root Cause: "Upon thorough investigation, we identified the root cause as a lack of proper oversight and contingency planning for our third-party logistics (3PL) partner. We failed to establish a secondary fulfillment solution and did not have a monitoring system in place to flag fulfillment delays from our 3PL in real-time. When our 3PL experienced an unexpected staffing shortage between [Start Date] and [End Date], 52 of our orders were not processed within the agreed-upon 24-hour SLA, causing them to be confirmed as shipped late."

This works because you’re not just blaming the 3PL; you’re taking responsibility for your failure to manage them and your lack of a backup plan.

Example 3: Unexpected Order Volume Overwhelmed the Team

This is a classic scenario for growing sellers who get a sudden surge in sales from a promotion or a viral social media post.

Weak Root Cause: "We got too many orders at once."

Strong Root Cause: "The root cause of our late shipments was our failure to create a scalable fulfillment workflow and staffing plan to manage sudden increases in order volume. On [Date], our daily order volume spiked by 300% due to a successful marketing campaign. Our two-person fulfillment team was not equipped to pack and ship this volume within our stated 1-day handling time, leading to a backlog of 78 orders that were shipped between 2-3 days late. Our operational procedures did not include a protocol for bringing in temporary staff or adjusting handling times during promotional periods."

This analysis is so effective because it quantifies the order spike (300%), identifies the specific operational weakness (no scalable staffing plan), and shows a deep understanding of why the system broke.

In every strong example, the seller provides data, accepts full responsibility, and diagnoses a fixable internal process. That's the formula for getting your appeal accepted.

Developing Bulletproof Corrective and Preventive Actions

Once you’ve dug in and figured out the real root cause of your late shipments, your Plan of Action needs to shift from why it happened to what you're going to do about it. This is where you lay out, in no uncertain terms, exactly how you've fixed the immediate problem and, more importantly, the systems you've put in place to guarantee it never happens again.

Let me be clear: Amazon's performance team reads this section with a microscope. Vague promises are the fastest way to get your appeal kicked back to you.

Your response has to be broken into two distinct parts: the immediate corrective actions and the long-term preventive actions. Think of it this way: corrective actions are about cleaning up the mess you made, while preventive actions are about future-proofing your entire operation.

Detailing Immediate Corrective Steps

This part of your POA is all about damage control. You need to show Amazon what you’ve already done to make things right for the customers who were let down. It’s your chance to demonstrate responsibility and prove you’re on top of your customer service.

Crucially, these actions must be completed before you hit submit on your POA. These aren't things you plan to do; they're things you've done.

For every late order that contributed to your metric dip, there needs to be a corresponding action. Be specific, be factual, and get straight to the point.

You need to show you've addressed the specific orders that pushed your Late Shipment Rate over that 4% cliff. The best place to find this info is right on your Account Health dashboard.

This dashboard is Amazon's source of truth. Referencing it shows you’re looking at the same data they are, which builds credibility instantly.

Here are a few concrete examples you can adapt for your own POA:

- Customer Communication: We have personally contacted every customer affected by a late shipment via Amazon's buyer-seller messaging service. In each message, we apologized for the delay and provided an updated, accurate delivery ETA.

- Order Audit: We have reviewed every single open order in our fulfillment queue to confirm our handling times are accurate and that all orders will be shipped by their "ship by" date.

- Inventory Reconciliation: We performed a full physical inventory count for our top 20 ASINs and reconciled the numbers with our stock levels in Seller Central to eliminate the risk of overselling.

These statements work because they're active, verifiable, and put the customer first. They prove you didn't just sit around waiting for a suspension—you took ownership and acted fast.

Building a Long-Term Preventive Strategy

This is the absolute heart of your amazon plan of action late shipment example. Honestly, Amazon cares far more about your future reliability than your past slip-ups. Your preventive actions need to show a fundamental, permanent upgrade to how you run your business.

Fluff like "we will monitor our metrics more closely" or "we will work harder" is completely useless here. You need to spell out specific, measurable, and systemic changes.

Amazon wants to see that you've installed new systems, not just new intentions. Your preventive measures should be so robust that the original root cause is now impossible to repeat.

Think about which part of your process broke down and how you can replace or reinforce it so it's unbreakable.

Systemic and Software Upgrades

Bringing in new technology is one of the most powerful ways to convince Amazon you've made a lasting change. Software doesn’t have a bad day or forget a step; it just executes the process you give it, every single time.

- Multi-Carrier Shipping Software: We have integrated our seller account with ShipStation, which gives us instant rate and delivery time comparisons across USPS, FedEx, and UPS. This ends our previous reliance on a single carrier and builds in automatic redundancy for peak seasons or carrier delays.

- Inventory Management System: We have implemented a new inventory management system, Linnworks, which syncs our warehouse stock levels with our Amazon listings in real-time every 15 minutes. The system also triggers automated low-stock alerts when any ASIN falls below a 14-day supply, making it impossible for us to oversell again.

Operational and Policy Changes

Not every solution needs to be a software subscription. Sometimes, the strongest changes are simple adjustments to your internal rules and workflows. This shows Amazon you're thinking strategically about your fulfillment capacity and limitations.

- Extended Handling Time: We have permanently changed our default handling time in our Amazon shipping settings from 1 day to 2 days. This gives us a crucial buffer to manage unexpected order spikes and guarantees we can meet our shipping promise, even on our busiest days.

- Staffing Protocols: We have created and implemented a new staffing protocol. When daily order volume exceeds 150% of our 30-day average, our fulfillment manager is now authorized to bring in two pre-trained temporary staff members from a local agency we have placed on retainer.

- Supplier Audits: We will now conduct quarterly performance reviews with our main suppliers to confirm their lead times and stock availability, ensuring their promises align with our forecasting needs.

When you present these kinds of detailed, bulletproof solutions, you're doing more than just asking for your account back. You’re making a rock-solid business case that you are now a stronger, more reliable, and more professional seller than you were before.

A Complete Amazon Plan of Action Late Shipment Example

Theory is one thing, but seeing a real-world, properly formatted Plan of Action is often the lightbulb moment for sellers trying to understand what Amazon's performance team actually wants. Let’s walk through a full example you can adapt for your own use.

The scenario here is a classic growing pain I see all the time: a seller puts all their eggs in one basket with a single shipping carrier. A regional weather event hits, their carrier has a two-day pickup delay, and that’s all it takes to push their Late Shipment Rate over the 4% threshold and get the account shut down.

Below is the exact structure and language that works for this kind of issue. I’ve added my own annotations to highlight why certain phrases and details are so critical to getting your appeal approved on the first try.

Subject: Plan of Action for Seller Account [Your Seller Name] Regarding Late Shipment Rate

To the Amazon Seller Performance Team,

We are writing to appeal the suspension of our seller account, [Your Seller Name], which was caused by our Late Shipment Rate exceeding the <4% performance target. We take full responsibility for this issue and have completed a thorough investigation into our fulfillment processes to identify and fix the root causes.

Our detailed Plan of Action is below. It outlines the specific cause of the late shipments, the immediate actions we have already taken to correct the problem, and the long-term systems we have put in place to ensure this will not happen again.

Part A: The Root Cause of the Problem

- After a full review of our shipping operations, we identified the primary root cause: our complete operational reliance on a single shipping carrier (USPS), with no backup carrier relationship established.

- Between [Start Date] and [End Date], our local USPS facility had a major service disruption from severe weather, which resulted in them missing our scheduled package pickups for 48 consecutive hours.

- Because we had no contingency plan or active account with a secondary carrier like FedEx or UPS, we were unable to dispatch 43 orders by their required ship-by date. This single point of failure is what directly caused our LSR to spike to 5.2%.

- We fully acknowledge that our internal procedure for managing carrier disruptions was inadequate and failed to protect our account health.

My Take: This root cause works because it demonstrates total ownership. It doesn't just pass the buck to the carrier; it pinpoints the internal failure—"complete operational reliance" and "no contingency plan." Providing hard data (43 orders, 48 hours, 5.2% LSR) proves you’ve done a real investigation, not just written a quick apology.

Part B: The Immediate Corrective Actions We've Taken

- We have already reviewed all 43 orders impacted by the shipping delay. We contacted every affected customer through Amazon's Buyer-Seller Messaging to apologize for the delay, providing them with their updated tracking details and expected delivery date.

- We have performed an immediate audit of all other open orders in Seller Central to guarantee they were shipped and scanned by their carrier on time. As of today, [Date of POA Submission], our unshipped order queue is at zero.

- We have immediately opened and fully set up new business accounts with FedEx (Account # [Your FedEx #]) and UPS (Account # [Your UPS #]). Both carriers are now integrated into our shipping software and ready for use.

My Take: See how this section uses past-tense language ("have reviewed," "have performed," "have opened")? That's intentional. This section is only for things you've already completed. Giving them your actual account numbers for the new carriers is a power move—it's verifiable proof that you've already implemented a core part of your solution.

Part C: The Long-Term Preventive Measures We've Implemented

- To permanently solve our single-carrier dependency, we have integrated our Amazon store with ShipStation, a multi-carrier shipping software. This system will now automatically compare rates and delivery times for every order, letting our team instantly switch to the best-performing carrier and pivot away from any future service disruptions.

- We have permanently updated our daily fulfillment SOP (Standard Operating Procedure). Our shipping manager is now required to check the official service alert pages for all three approved carriers (USPS, FedEx, UPS) first thing every morning. If any disruption is found, they will immediately stop printing labels for that carrier and reroute all packages through an alternative.

- We have changed our default handling time within our Amazon Shipping Settings from 1 day to 2 days. This creates a permanent buffer to absorb potential carrier delays or unexpected order spikes, ensuring we can always meet our ship-by date promise to Amazon's customers.

We are confident that these actions fully resolve the root cause of our performance issue and will keep our Late Shipment Rate well below the 4% requirement from now on. We appreciate you taking the time to review our appeal and look forward to having our selling privileges reinstated.

Sincerely,

[Your Name]

[Your Seller Name]

[Your Phone Number]

Still Have Questions About Amazon POAs?

When your Amazon account hangs in the balance, it’s natural to have a million questions running through your mind. A suspension is incredibly stressful, but getting clear, straight-up answers can make all the difference.

Let's cut through the noise and tackle the questions I hear most often from sellers facing this exact situation.

How Long Does Amazon Take to Review a POA?

This is the big one, and unfortunately, the answer is "it depends." Most of the time, you'll hear back from Amazon's Seller Performance team within 24 to 48 hours.

But if your case is complex or you get flagged during a busy period like Q4, it can stretch to a week or even longer. The waiting is the hardest part, I know. But whatever you do, don't send follow-up emails chasing them for an update. Bombarding them can actually push your case to the back of the line and drag out the process.

Submit your POA once, then wait.

Should I Contact Seller Support While I'm Waiting?

It's tempting to try and get an update from someone—anyone. But calling or opening a case with general Seller Support won't speed things up. The Seller Performance team is a completely separate, internal department.

Think of it this way:

Contacting Seller Support for a POA status update is like asking a bank teller about your mortgage application—they work for the same company, but they're in a different department and have zero access to the information you need.

Focus that energy on making sure your first submission is as rock-solid as possible.

Can't I Just Use a Template I Found Online?

Using a template to understand the structure of a POA is fine. But copying and pasting a generic amazon plan of action late shipment example is a one-way ticket to rejection.

Amazon's reviewers see thousands of these things. They can spot a copied template from a mile away.

Your POA has to be about your business and your specific failures. A generic plan screams that you haven't bothered to do a real investigation, and they will shut it down fast. Personalize every single detail to show you understand what went wrong and how you've fixed it.

What Happens If My First POA Gets Rejected?

First, take a breath. It’s not the end of the road. When Amazon rejects a POA, they usually give you a short, often vague, reason why it wasn't good enough.

That feedback is your roadmap. Read it carefully.

- Did they say your plan wasn't "detailed" enough? That’s code for weak or generic preventive actions.

- Did they say you didn't address the "root cause"? That means you need to dig deeper and be more honest about what really happened.

Revise your POA with more specific, concrete details based on their feedback and resubmit it. Many sellers I've worked with get reinstated on their second or third try once they finally give Amazon the level of detail it's looking for.

Navigating an Amazon suspension can feel like you're lost in a maze. The good news is, you don't have to do it alone. The experts at Clickstera Solutions LLC specialize in full-service account management and have a proven track record with reinstatements. We've helped over 100 brands scale their operations and get through challenges just like this one. If you need a partner to craft a winning POA and get your business back on its feet, visit us at https://clickstera.com.